Description

If you missed the educational sessions at Reliable Plant 2012, you can still get the conference proceedings on CD-ROM. It includes the presentations in PDF format from nearly every learning session in each of the two co-located conferences: Lubrication Excellence 2012 and Reliability World 2012.

The real-world case-studies at Reliable Plant 2012 were chock-full of practical, experience-based information and tools for lubrication and reliability programs. Here's an example of what you'll find in the proceedings:

Key Performance Indicators

What Works

What Doesn't Work

And Plenty of How To's

Published: 2012

Format: CD-ROM

Table Of Contents:

Lubrication Excellence 2012

The True Cost of Filtration

Christian Bauer, Pall Corporation

Replacing Boiler Feed Pump and Main Turbine Oil Conditioners

Curtis Benjamin, Southern Company and Rob Estill, Henek Fluid Purity Systems

How to Effectively Use Analytical Ferrography

Aaron Black, POLARIS Laboratories

Lubrication Journey: Setting the Cornerstone for Improved Plant Reliability

Paul Bonorden, Invista

Getting the Most from Your Filter Cart

Wes Cash, Noria Corporation

Extending Cutting Fluid Life

Duk Yung Cho, Solge Corporation

Outstanding ROI When Lubrication Programs Are Supported by International Standards

Ray Garvey, Emerson Process Management

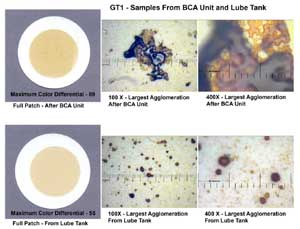

Turbine Lube Oil: Long Term Study of Balanced Charge Agglomeration Use

Raymond Gomes, Isopur Fluid Technologies, Inc.

How to Use a Lubrication Audit to Improve Equipment Reliability

Tom Hiatt, Covance Inc. and Wayne Ferguson, Eli Lilly and Company (retired)

FT-IR Oil Condition Monitoring: From the Lab to On-site Measurements

David Hilligoss, PerkinElmer ASLS

Visual Lubrication Reliability Best Practices

Mark D. Jones Sr., Lubrication Engineers

Lubrication Basics and Best Practices

Greg Kayes, Kluber Lubrication North America

Improving Energy Efficiency with Proper Gear Oils

Greg Kayes, Kluber Lubrication North America

Grease Can Talk: Grease Analysis for Wind Turbines

Ruediger Krethe, OilDoc GmbH

Increasing Uptime of Ship Unloader's Hydraulic Operation

Juan Bautista L Lee, Center for Reliability Excellence

Maximizing the Value of Oil Analysis for Wind Turbines

Greg Livingstone, Amar Pradhan Fluitec

Methods of Application for Open Gear Lubricants and Their Selection

Lawrence Ludwig, Schaeffer's Specialized Lubricants

The Do's and Don'ts of Improving Lubrication Skills

Bill Lyons, Holcim (US) Inc.

Efficient Removal of Water from Oil via a New Membrane System

Sudip Majumdar and Stuart Nemser, Compact Membrane Systems

Evolution to a World Class PM Facility

Ted Melencheck, Cargill Deicing Technology

Environmentally Safe Lubricants in the Real World

Mark Miller, Terresolve Technologies Ltd.

Removing Dissolved Soft Contaminants from Turbine Oil

Steffen Nyman, C.C.JENSEN INC

Getting Back on Track to Lubrication Excellence

Pete Oviedo, Noria Corporation

Oil Sampling – The Very Best Practices

Josh Pickle, Noria Corporation

Handling, Storage and Management of Lubricants

Josh Pickle, Noria Corporation

Managing Water Contamination to Maintain Effective Lubrication

Gregory Sedelmeier, Shell

Interpretation of Oil Analysis Data

Robert Scott, Lubeworks Ltd.

Correction of Oil Analysis Wear Data for Make-up Oil Dilution

Robert Scott, Lubeworks Ltd.

Setting Effective Oil Analysis Alarm Limits

Matt Spurlock, Noria Corporation

Using Criticality to Help Drive Oil Analysis Strategy

Matt Spurlock, Noria Corporation

Using Ferrography to Provide Early Warning of Abnormal Wear

Knv Subrahmanyam, Predict Technologies India

Oil Analysis Case Studies: The Good, the Bad, and the UGLY

Rendela Wenzel, Eli Lilly and Company

Effective Electric Motor Lubrication

Jeremy Wright, Noria Corporation

Reliability World 2012

Reliability is a Mindset

Eyad Al-Basrawi, Saudi Aramco

Improving OEE Using "Honky-Tonk" to Reduce Costs and Increase Throughput

Riad Ardahji, Toyota Boshoku, Americas

Pump Performance Curves: An Effective Reliability Tool

Larry Bachus, Bachus Co Inc.

Going Deep to Prevent Catastrophic Failure in a Platinum Mine

Harold Joyce, PdMA Corporation

How to Introduce a New Reliability Program

Paul Bonorden, Invista

Thermal Growth and Machinery Alignment

Pedro Casanova, LUDECA Inc.

Implementing Operator Maintenance

John Crossan, John Crossan Consulting and Randy Quick, Automation & Control Services

Investing in Reliability Through International Certification

Marcello Gracia, CONFIALUB/Noria

Asset Management Master Planning: Evolution of Maintenance Master Planning

Mike Greenholtz, Genesis Solutions

When Decibels Aren't Enough

Jim Hall, Ultra-Sound Technologies Training Systems (USTTS)

Tools and Techniques for Understanding Chloride Stress Corrosion Cracking

Greg Henson and Chantel Booth, Eli Lilly and Company

The Critical Role of a Reliability Engineer

Rich Jansen, Life Cycle Engineering

Root Cause Analysis vs. Shallow Cause Analysis: What's the Difference?

Bob Latino, Reliability Center Incorporated

Technological Advances in Wear Debris Particle Analysis

Violet Leavers, V4L Particles LTD.

Solution for Monitoring Low RPM Bearings

Patrick Parvin, SPM Instrument

TPM Implementation Considering Organizational Culture

George Péczely, A.A. Stádium Ltd.

A Holistic Approach to Assessing the Condition of Process Machinery

Robert Perez, Enterprise Products

Cloud Computing - Another Buzzword or Leveraging Technology?

Kenneth Piety, Azima DLI

The Often Overlooked Role of Fasteners in Reliability

Jerry Putt, Goodyear Tire & Rubber Co.

Equipment Installation for Optimum Reliability

Jerry Putt, Goodyear Tire & Rubber Co.

The Key to Improving Your Availability is FRACAS

James Taylor, Machinery Management Solutions, Inc.

The Path to Maintenance Excellence

Wayne Vaughn, Vesta Partners

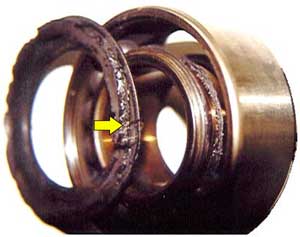

The VFD Story: Hidden Damage of Shaft Currents

Dwight Vicars, Inpro-Seal LLC

Preventing Equipment Failures with Condition Based Maintenance Tools

Rendela Wenzel, Eli Lilly and Company

Lower Your Operation Cost through a Focused Improvement Effort

Bruce Wesner, Life Cycle Engineering